Barite is an important mineral resource and plays an extremely important role in many industries and fields. The quality of barite ore is generally poor, and it needs to be sorted and purified to increase the content or specific gravity of barite. So what is the processing equipment for barite, and what is the method of dressing for barite? Customizable Nylon Self- locking Cable Ties Free samples Nylon Cable Tie

Product Description

A cable tie , also known as a zip tie or tie-wrap, is a type of fastener, especially for binding several electronic cables or wires together and to organize reusable cables and wires.

In its common form, the Nylon Cable Ties consists of a tape section with triangular teeth that slope in one direction. The head of the cable tie has a slot with a flexible pawl that rides up the slope of these teeth

when the tape is inserted. The pawl engages the backside of these

Feature

1. Type: Releasable Type nylon beaded knot cable tie

Nylon ties

Nylon ties (ISO ,TS16949,UL)

1.Material:Nylon 66 ,94V-2.

2.Temp Resistance:-40 ℃ to 85℃ ;short time 150 ℃

3.Color:Natural(or white,standard color),UV black and other colors are available as requested.

4.Feature:Heat-resisting,and erosion control,insulate well and not apt to age.

5.Package:As per customer's requirement.

6.Ideal Applications: Color coding,Identification,Packaging Continuity, and Bundling Aesthetics.

7.Application:Widely used to bundle cable and wire or other things in the industry of electrical &electronic,lighting,hardware,pharmaceutical,chemical,computer etc.It's easy to use.

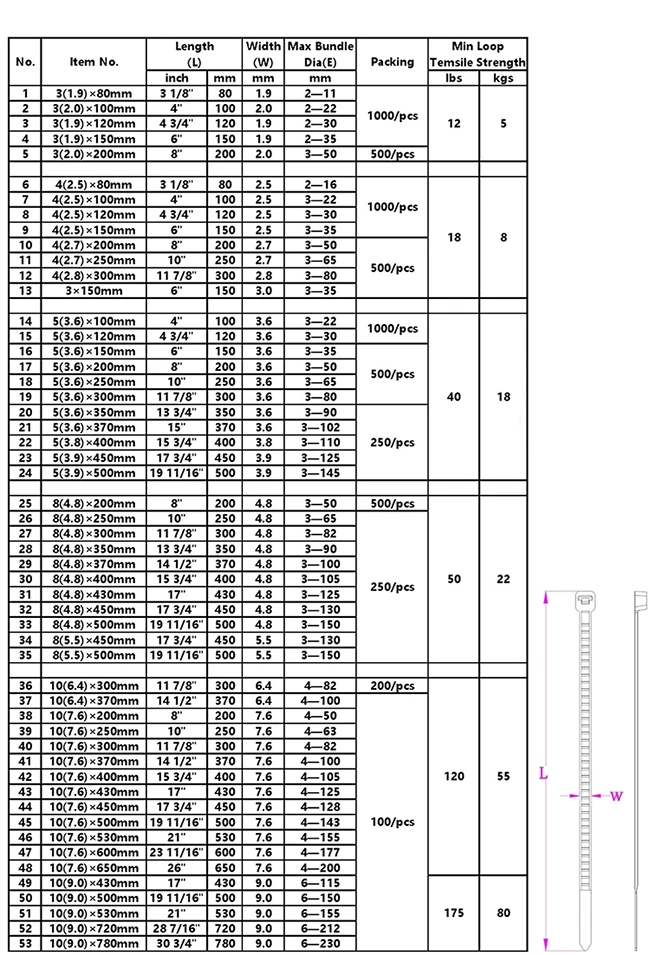

8.Specifications of Self-Locking Cable Ties:

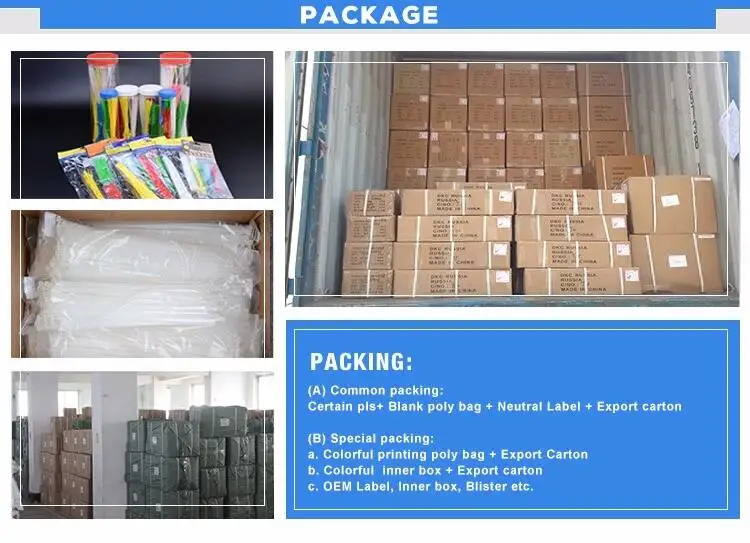

Packing of nylon ties

A. Common Packing: 100Pcs + Polybag + Label + Export Carton

B. Customized Packing: Header card packing, Blister with card packing, Double blister packing, Canister packing, other packing can be supplied according customers request

Width: 1.8-12mm

Length: 60-1200mm

1.Welcome to visit our factory !

2.Free Samples !

Nylon Cable Ties Self-Locking Nylon 66 Cable Tie,UV Black Nylon Cable Tie,UV Black Nylon Cable Tie,High Quality Cable Tie,Nylon Cable Tie with Label,Plastic Self Locking Nylon Wire Cable Tie KEYUACE Materials Co., Ltd. , https://www.insulationtubing.com

Barite ore can be divided into 6 types according to its mineral composition:

1 Single mineral barite ore BaSO4 content 80% -98%, very few associated minerals.

2 Quartz -barite ore This type of ore is mainly composed of barite and quartz, and the content of quartz in the ore is 30%-45%. The grain size of quartz affects the quality of the ore to a large extent. The finer the grain size of the inlay, the more difficult it is to sort.

3 fluorite -barite ore and fluorite are the main minerals of this type of ore; other associated minerals are quartz and calcite .

â‘£ sulfide ore - such barite ore and barite ore mainly composed of iron sulfide, copper sulfide, zinc sulfide and lead sulfide, etc., which is associated minerals are quartz, calcite and fluorite.

5 Iron ore-barite ore is mainly composed of barite ore and iron ore (magnetite, hematite, goethite, etc.). Other associated minerals are quartz and calcite.

6 Clay or sandy barite ore This type of ore contains different amounts of clay, rock debris, single mineral barite crumbs and so on.

The existing barite beneficiation equipment process usually adopts the re-election method. The method has the advantages of large particle size, wide grain size and large ore processing capacity, and the re-election method plays a major role in the field of barite beneficiation. The re-election method is used to purify and process barite ore. It has the advantages of high efficiency, energy saving and environmental protection. It can also obtain ideal beneficiation index. It has excellent effect on the recovery and treatment of coarse and fine grain barite. In the barite concentrator, the re-election method has become the core method.

The process of barite beneficiation is mainly as follows: the barite ore is washed and sieved, crushed, graded and demineralized, and then the jigging beneficiation process can obtain fine concentrate with good quality, and the product grade can reach over 88%. The crushing of barite is generally carried out by a jaw crusher or an impact crusher, and the fine crushing is generally carried out by a roller crusher. At the same time, the selection can also be used for heavy medium drum sorting machine, cone classifier, shaker, screw machine, etc. The barite inlay has a particle size greater than 2 mm, and can usually be sorted by a heavy medium and jigging. The maximum particle size for heavy media sorting is 50 mm. The maximum particle size of wet and dry jigging is about 20mm. The inlay size is less than 2 mm and can be sorted by a shaker or a spiral classifier. Before the selection, a hydrocyclone should be used to remove the mud to improve the sorting effect. The jig can effectively select the coarse, medium and fine-grain barite ore, and the ore dressing effect is ideal, which can effectively increase the specific gravity of the barite and utilize the circulating water operation. The beneficiation process does not require the use of chemicals, and does not pollute the environment. It is a new type of high-efficiency, energy-saving and environmentally friendly barite beneficiation method.

2. Material: Nylon 66

3. Feature: Heat-resisting, erosion control,insulate well and not apt to age

4. Operation Temperature: -40°C to 85 °C

5.Colour: Natural (white or standard colour), UV black and other colours are available

6.Certificates: UL, CE, ROHS, REACH,UV , ISO9001:2000

7.Package: Polybag + Label

Features

Product Dimension

Detailed Images

Packaging & Shipping

Our Services

FAQ