Safety By using the Elios 3, the need for working at height, setting up scaffolding, or entering confined spaces is eliminated. This significantly reduces the risks involved in inspecting ship hulls and tanks. Speed The Elios 3 can be deployed within 30 minutes of arrival on-site, saving thousands of hours that would otherwise be spent on scaffolding and manual inspections. Localization The Elios 3 provides 3D models of the inspected areas, making it easier to locate and revisit specific points of interest for further analysis or maintenance work. Reporting C-Bird completed the required UTM and close-up survey for the ship’s 5-year inspection, and the data was certified by a class society, ensuring compliance with industry standards. Every five years, all ships must undergo a special periodical inspection, with more frequent checks for older vessels. As ships age, these inspections become more rigorous, often requiring major assessments every 30 months after the vessel is over 15 years old. These inspections are essential to ensure the ship is safe to operate and can be extremely costly, with ships waiting in dry dock for repairs. A key part of this process involves ultrasonic thickness (UT) measurements of the hull and visual inspections of critical areas. These inspections are vital for identifying hidden structural issues that may not be visible to the naked eye. Historically, accessing UT inspection points required extensive labor. Teams of up to 30 people would enter the space, set up scaffolding, and then climb to take measurements. This method posed significant risks, including falls from height and the potential for debris to damage internal systems. Scaffolding also added to the cost and time of the inspection, with the ship often needing to be in dry dock for several days. The costs associated with traditional methods can be staggering, with scaffolding alone costing between $300,000 and $700,000, and dry dock charges reaching millions of dollars. C-Bird, a specialized ship inspection company, has been using the Elios 3 for UT inspections on vessels over 15 years old. They’ve found that the drone is faster and safer than traditional methods while still gathering the necessary UT and visual data. This not only improves safety but also cuts down on the time and money spent on scaffolding, speeding up the entire inspection process. A UT inspection might involve entering a confined space inside a ballast tank. C-Bird was tasked with inspecting 12 oil tanks in a medium-sized ship. Malcolm Connolly, C-Bird’s CEO, was responsible for gauging measurements and close-up inspections as part of the ship’s periodic survey. The tanks measured 38 x 28 x 20 meters, with 6 transverse web frames in each cargo oil tank (COT), and transverse bulkheads separating them. For this project, the team used the Elios 3 equipped with its new UT payload. The drone provided detailed LiDAR mapping and high-quality visual inspections. Visual records had to be captured at arm’s length, which the drone could do without the need for scaffolding or confined space entry. As a product advisor and beta-tester for the new UT payload, Malcolm saw this as an ideal opportunity to test the drone in a real-world NDT environment. Instead of relying on traditional methods, C-Bird used the Elios 3 and its UT probe to inspect the 12 oil tanks. With guidance from a class inspector, they completed the task efficiently. Once the equipment was onboard, the inspection began immediately—saving thousands of hours compared to scaffolding. The drones flew around each tank, taking measurements in multiple locations as specified by the inspection plan and any additional requests from the class surveyor. A close-up view of the COTs during inspection with the Elios 3. The Elios 3 made visual inspections more efficient. Pilots were able to collect both visual and UT data during flights, providing clear images of the inspected areas from the required distance. This allowed C-Bird to complete the work twice as fast, with one drone focused on visuals and the other on UT measurements. The results included clear visual displays of points of interest along with UT spot measurements. An example of a point cloud generated by the Elios 3 UT payload, showing UT spot measurements. C-Bird compiled the data into the required format and submitted it for review. This process was much faster than traditional methods because all data was collected in one go, eliminating the need to move around scaffolding or adjust MEWPs. Following a two-year program of successful pilot projects, C-Bird and their results using the Elios 3 and UT payload were certified by the American Bureau of Shipping, one of the world’s leading class societies. They were recognized as an approved service provider for ESP hull gauging (Enhanced Survey Program), marking a first in the industry. This certification highlighted the value of C-Bird’s achievements with drone-based inspections. Watch how the Elios 3 uses live 3D modeling to guide the drone and make a UT measurement, marking it as a point of interest for reporting. The Elios 3 offered C-Bird five main benefits: easy localization of UT spot measurements in a clear point cloud, easier access to hard-to-reach areas while maintaining safety, reliable and certified results, versatility across different environments, and the ability to provide detailed reports that meet class society requirements. These advantages helped C-Bird stand out from competitors and proved the value of the drone as a powerful tool for ship inspections. C-Bird plans to continue using the Elios 3 and its UT payload for inspections across various industries, from maritime to oil and gas. The efficiency, safety, and quality of data achieved through this method have opened new possibilities for challenging inspections in confined spaces. C-Bird is excited to apply the Elios 3 to future projects and push the boundaries of what’s possible in ship inspections. Discover more about the Elios 3 and its UT payload Channel Steel,Channel Steel Section,Galvanized Channel Steel Channel,U Type Channel Shandong Great Steel Co.,Ltd , https://www.great-steel.comThe Elios 3 UT Payload: Avoiding 15,000 Hours Of Work At Height For Hull Inspections

Key Benefits at a Glance

Traditional UT Inspections on Ships

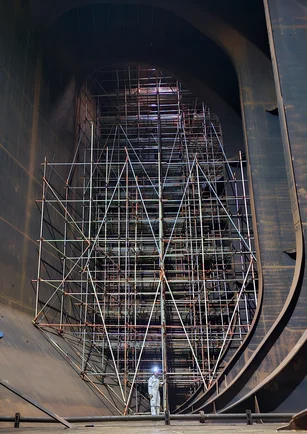

Image right: Scaffolding requires large teams and poses serious safety risks. It's time-consuming and expensive.

Image right: Scaffolding requires large teams and poses serious safety risks. It's time-consuming and expensive.How UT Drone Inspections Benefit the Maritime Industry

Conducting a Ship UT Inspection with the Elios 3

Certified Results from Using the Elios 3 for a UT Ship Inspection