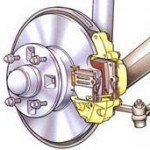

Is your Toyota Sienna making strange noises when you brake? Squeaking or grinding could be a sign that it's time to replace the brake pads. Here’s a step-by-step guide to help you do it yourself. Before diving into this project, make sure you have enough space and time to work comfortably. It's also important to gather all the necessary tools. A well-prepared setup can make this job much easier and less stressful. Rushing or working in a tight, poorly lit area can lead to mistakes and even damage your vehicle. To replace the brake pads on your Toyota Sienna, you'll need a floor jack, jack stands, a set of sockets, and a torque wrench. Follow these steps carefully: Congratulations! You've successfully replaced the brake pads on your Toyota Sienna. Need help? Thermoplastic Polyurethanes TPU

Thermoplastic polyurethane elastomer (TPU) is a type of elastomer that can be plasticized by heating and dissolved in solvents. It has excellent comprehensive properties such as high strength, high toughness, wear resistance, and oil resistance, and good processing performance. It is widely used in defense, medical, food and other industries.

Thermoplastic Polyurethane (TPU) is a type of polymer resin that is known for its flexibility, durability, and versatility. It is a thermoplastic material, which means it can be melted and reprocessed multiple times without losing its original properties. Waterproof Tpu Films,Good Tpu Shoes Materials,Transparent Tpu Hose,Custom Thermoplastic Polyurethanes Tpu XUCHUAN CHEMICAL(SUZHOU) CO., LTD , https://www.xuchuanchem.com

The Repair Process

Related Posts

TPU is commonly used in various industries, including automotive, electronics, footwear, and sportswear. It is often used to make products such as phone cases, cables, hoses, seals, gaskets, and inflatable structures.

Some key properties of TPU include:

1. Flexibility: TPU has excellent flexibility, allowing it to bend and stretch without breaking. This makes it suitable for applications where flexibility is required, such as in shoe soles or flexible electronic components.

2. Abrasion resistance: TPU has good resistance to abrasion, making it suitable for applications that require durability and resistance to wear and tear.

3. Chemical resistance: TPU is resistant to many chemicals, including oils, solvents, and greases. This makes it suitable for applications where exposure to chemicals is expected.

4. Weather resistance: TPU has good weather resistance, meaning it can withstand exposure to sunlight, moisture, and extreme temperatures without degrading or losing its properties.

5. Adhesion: TPU has good adhesion to various substrates, allowing it to be easily bonded or laminated with other materials.

Overall, TPU is a versatile material that offers a balance of flexibility, durability, and chemical resistance, making it suitable for a wide range of applications.

Toyota Front Brake Pad Replacement – 04465-35290

Toyota Front Brake Pad Replacement – 04465-35290  Toyota Yaris Maintenace – Change Brake Pads

Toyota Yaris Maintenace – Change Brake Pads  Installing New Brake Pads

Installing New Brake Pads  Toyota Camry Maintenance – Replace Front Brake Pads

Toyota Camry Maintenance – Replace Front Brake Pads  Toyota Sienna Awarded One Of Best Family Cars For 2014 – Kelley Blue Book

Toyota Sienna Awarded One Of Best Family Cars For 2014 – Kelley Blue Book  Toyota Sienna Accessories

Toyota Sienna Accessories