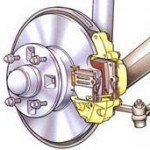

Are your Toyota Sienna brake pads squeaking or grinding? Replace them today. Here is how to do it. Before you begin this repair on your own, you will want to make sure you have ample workspace and time. Plus, make sure you have a full complement of automotive tools at your disposal. By taking your time and having the right tools/workspace, this job is fairly straightforward. Rushing, working in a dim/cramped space, or not having the right tools can cause this repair to turn into a nightmare. In order to do this repair, you will need a floor jack or hydraulic pump, jack stands, an assortment of sockets, and a torque wrench. Then, follow these steps: Congrats! You just changed the brakes in your Toyota Sienna. Questions? PU resin is one of the most suitable base materials for ink.

We can also provide suggestions about product formula.

PU resin, also known as polyurethane resin, is a type of synthetic resin that is widely used in the production of inks. It is a versatile material that offers various benefits for ink formulations.

One of the main advantages of using PU resin in ink is its excellent adhesion properties. It forms a strong bond with different substrates, including paper, cardboard, plastic, and metal, ensuring that the ink adheres well to the surface and resists smudging or rubbing off.

PU resin also provides good gloss and transparency, resulting in vibrant and visually appealing prints. It enhances the color intensity and clarity of the ink, making it suitable for high-quality printing applications.

In addition, PU resin offers excellent resistance to water, chemicals, and abrasion. This makes the ink more durable and long-lasting, ensuring that it remains intact even under harsh conditions.

Furthermore, PU resin can be formulated to have fast drying properties, allowing for faster production speeds in printing processes. It also has good flexibility and elasticity, which helps prevent cracking or flaking of the ink film.

Overall, PU resin is a popular choice for ink formulations due to its excellent adhesion, gloss, transparency, resistance, and drying properties. It is commonly used in various printing applications, including packaging, labels, decals, and graphic arts.

Customed Logo of Print Inks,Pu Resin For Inks,Solvent-Based Printing Inks,Waterproof Water-Based Ink XUCHUAN CHEMICAL(SUZHOU) CO., LTD , https://www.xuchuanchem.com

The Repair

Related Posts

**Tips for a Smooth Brake Pad Replacement**

Changing your own brake pads can be a rewarding DIY task that saves you money and keeps your vehicle running safely. However, it's important to approach the job carefully. Always ensure your car is properly supported on jack stands before working under it. It's also a good idea to clean the area around the brake components before removing them to avoid dirt and debris from entering the system.

When replacing the brake pads, take note of the orientation of the old ones. The new pads should match exactly to maintain even braking performance. Don't forget to lubricate the caliper slides and hardware with high-temperature grease to prevent future noise and sticking. After installation, test your brakes gently to make sure they're functioning correctly.

If you're unsure about any step, don't hesitate to consult a professional mechanic. Safety should always come first when working on your vehicle. With the right tools and a bit of patience, you can successfully complete this maintenance task and keep your Toyota Sienna in top condition.

It can provide the ink with good pigment dispersity, adhesive force, and some other performance like heat resistance, adhesion with OPP or PE film and so on.

PU resin of ink can be divided into 3 types because of the ink types, including inside composite ink, surface composite ink and water-based composite ink. But all of the them are suitable for gravure printing rather than other printing methods.

We have different resin which can be suitable for NC or ester. They can show various abilities like boiling water resistance, good adhesion with OPP, low odor and so on.

Toyota Front Brake Pad Replacement – 04465-35290

Toyota Front Brake Pad Replacement – 04465-35290  Toyota Yaris Maintenace – Change Brake Pads

Toyota Yaris Maintenace – Change Brake Pads  Installing New Brake Pads

Installing New Brake Pads  Toyota Camry Maintenance – Replace Front Brake Pads

Toyota Camry Maintenance – Replace Front Brake Pads  Toyota Sienna Awarded One Of Best Family Cars For 2014 – Kelley Blue Book

Toyota Sienna Awarded One Of Best Family Cars For 2014 – Kelley Blue Book  Toyota Sienna Accessories

Toyota Sienna Accessories