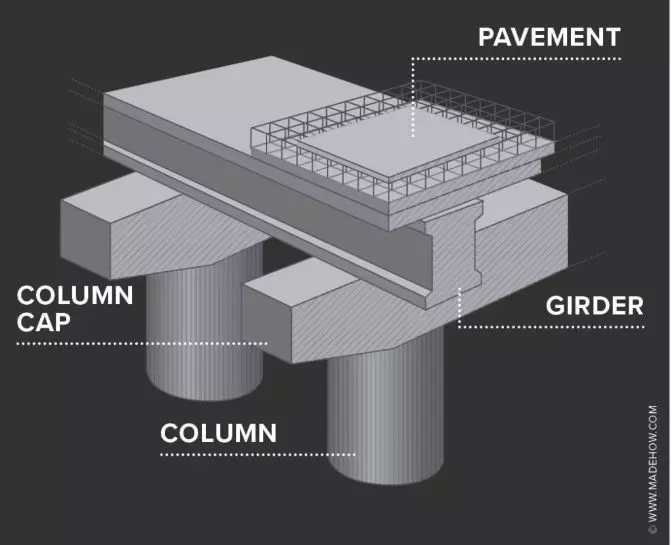

Bridge inspections are a critical part of infrastructure maintenance, allowing engineers to detect small defects and potential issues before they escalate into major problems. These inspections help ensure the safety of millions of people who rely on bridges every day. If a bridge is not inspected regularly, even minor issues can lead to catastrophic failures—like collapses or structural damage—that can result in serious injuries or even loss of life. That’s why bridge inspections are legally required in most countries around the world. In this guide, we’ll explore what bridge inspections involve, the different types and techniques used, the challenges inspectors face, regulatory requirements, and how modern technology like drones is changing the game for safer and more efficient inspections. While many people don’t think about the bridges they drive over daily, there are over 700,000 bridges in the U.S. alone, and all require regular inspection and maintenance to ensure they remain safe for public use. Although practices vary by country, most require that bridges be inspected at least once every two years. During these inspections, engineers look for signs of wear, cracks, corrosion, or other issues that could compromise the structure’s integrity. The traditional method involves using a "snooper truck"—a specialized vehicle with a bucket that allows inspectors to get up close to hard-to-reach areas of the bridge. This method has been used for decades but comes with its own set of limitations. Snooper trucks can climb steep inclines and operate in water, but they are expensive to purchase or rent, and their use often requires traffic control, which can be disruptive. There are several types of bridge inspections, each serving a specific purpose: While visual inspections are the most common, other methods include acoustic testing, thermal imaging, and ground-penetrating radar (GPR). These tools help identify hidden issues like delamination, cracks, or internal damage that aren't visible to the naked eye. One of the biggest challenges is accessing difficult areas without putting workers at risk. Drones are increasingly being used to overcome these obstacles, providing high-quality images and data without the need for dangerous climbs or traffic disruptions. Bridge inspections are not without their difficulties. Traffic control, staffing, access to tight spaces, and high costs are just a few of the challenges inspectors face. For example, a snooper truck rental can cost up to $2,500 per day, and staffing adds to the expense. However, new technologies like drones are helping reduce risks and improve efficiency. Drones can reach areas that are otherwise inaccessible and provide real-time data without disrupting traffic or putting workers in harm's way. Each country has its own set of regulations governing bridge inspections. In the U.S., the National Bridge Inspection Standards (NBIS) outline the frequency and procedures for inspections. For example: States may also have stricter rules, including expanded definitions of what constitutes a bridge, increased inspection frequency, or variations in the types of inspections required. Bridge inspectors are responsible for identifying signs of wear and tear, such as cracks, rust, corrosion, or movement in the structure. They also check for issues with bearings, electrical systems, and utility infrastructure attached to the bridge. Electrical components are often overlooked, but they play a crucial role in the safety and functionality of a bridge. Inspectors must look for outdated wiring, damaged connections, or poor repair work that could pose a risk. To conduct official bridge inspections, inspectors usually need certification. In the U.S., the Federal Highway Administration (FHA) oversees training and qualifications for bridge inspectors under the National Bridge Inspection Standards (NBIS). Proper training ensures that inspectors can accurately assess the condition of a bridge and report findings that meet legal and safety standards. Most countries have established standards for conducting bridge inspections. In the U.S., the Federal Highway Administration sets guidelines that cover everything from inspection procedures to maintenance policies. These standards help ensure consistency and safety across the nation’s vast network of bridges. As technology evolves, so do the methods used to inspect and maintain them, making the process more efficient and less risky for workers. Coating Material Changzhou Dahua-Luckypower , https://www.czluckypowertech.comBridge Inspections — Everything You Need to Know

BRIDGE INSPECTIONS ARE A CRUCIAL PART OF MAINTAINING KEY INFRASTRUCTURE AND ENSURING SAFETY—LEARN MORE ABOUT THEM IN THIS GUIDE.

What is a Bridge Inspection?

Bridge Inspection Types, Techniques, and Challenges

BRIDGE INSPECTION TECHNIQUES

UNIQUE CHALLENGES FOR BRIDGE INSPECTIONS

Regulatory Considerations for Bridge Inspections

What Does a Bridge Inspector Do?

BRIDGE INSPECTION CERTIFICATION

BRIDGE INSPECTION STANDARDS