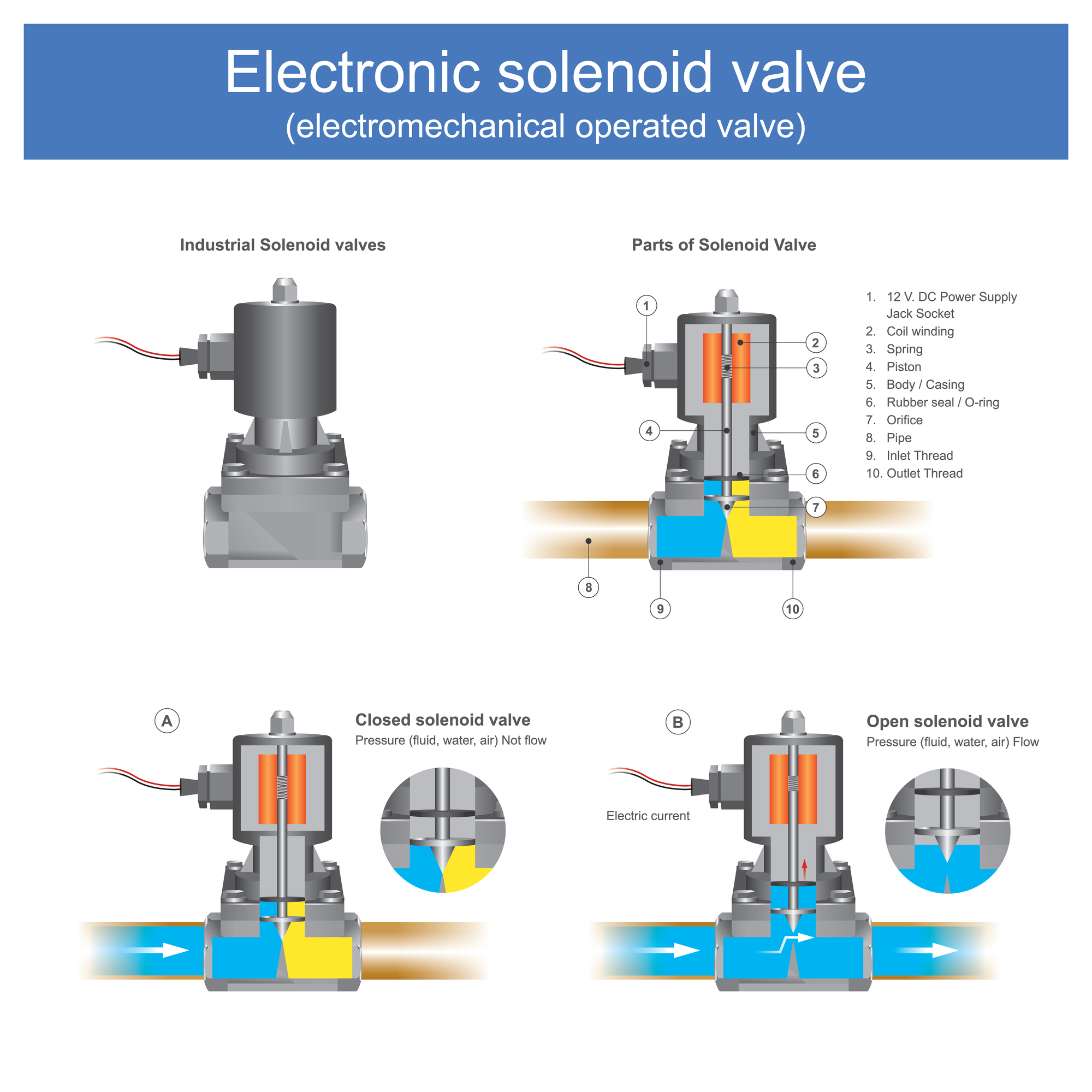

When it comes to brewing, every single detail matters, from the type of grains used to the temperature at which fermentation occurs. One often-overlooked but crucial component in this intricate process is the solenoid valve. These valves are responsible for managing the flow and quality of liquids throughout the brewing journey, ensuring that each batch turns out as expected. Solenoid valves are indispensable for maintaining control over the movement and flow rate of liquids in brewing. Their ability to provide exact precision and reliability makes them vital for different stages of the brewing process. As brewing technology continues to evolve, the demand for higher efficiency and consistency has driven significant advancements. At the core of this transformation lies the following: Choosing the appropriate solenoid valve is critical based on the specific needs of a brewing operation. In the complex art of brewing, even the smallest components play a significant role. Solenoid valves, in particular, are vital for managing the flow and quality of liquids, directly impacting the efficiency, safety, and flavor consistency of the brewing process. For breweries aiming to improve their operations, focusing on the right solenoid valves isn't just a technical choice—it’s a dedication to excellence in brewing. Answer: Yes, indirectly. By providing precise control over the flow and temperature of liquids, these valves ensure consistency in the brewing process, which is essential for preserving the intended flavor profile of the beer. Consistent temperatures and ingredient mixing result in a more reliable and higher-quality end product. Answer: A solenoid valve is an electromechanically operated valve designed to control the flow of liquids. In brewing, it operates by opening or closing in response to an electric current, allowing for precise control of liquid ingredients such as water and wort throughout various stages of the brewing process. This precision guarantees consistency in flavor and quality in each batch of beer.

plastic pipe making machine in Pipe Extrusion Machine production line

Plastic pipe making machine application:

Plastic pipe application and usage amount is far ahead in the plastic pipe field,good surface hardness and tensile strength, good anti-aging, high safety factor, it is widely used in electrical cable pipe,water supply pipe,drain pipe, agricultural water supply system, architectural water supply system, pavement of cables etc.

Production line with high efficiency single screw extruder and through the spiral or basket type Mould by multi - Crawler traction machine vacuum sizing cooling and. As is known to all, large-diameter PE pipe are tractive pipe variety, KR specially developed rapid traction switching device, so as to solve the the problem. By the appropriate transformation part of the unit, you can achieve a two-layer or multi-layer co extruded, replacing the extruded layer material or add special materials according to the requirements of the use, such as flame retardant, antistatic, corrosion resistance, nano antibacterial materials, greatly improving the pipe use, reduce raw material consumption, thereby reducing the cost of pipes. Plastic Pipe Making Machine,Plastic Tube Making Machine,Plastic Pipe Manufacturing Machine,Plastic Tube Manufacturing Machine KonRun Intelligent Machinery(Ningbo) Co., Ltd. , https://www.konrunmachine.comIntroduction

Precision in Liquid Handling

Selecting the Right Solenoid Valve

Conclusion

Frequently Asked Questions:

Can the use of solenoid valves affect the taste of the beer?

What exactly is a solenoid valve and how does it function in brewing?

Production line using PLC control system, man-machine dialogue interface, simple operation, stand-alone adjustment, the full board linkage, automatic fault alarm, production and reliable.

Product Description