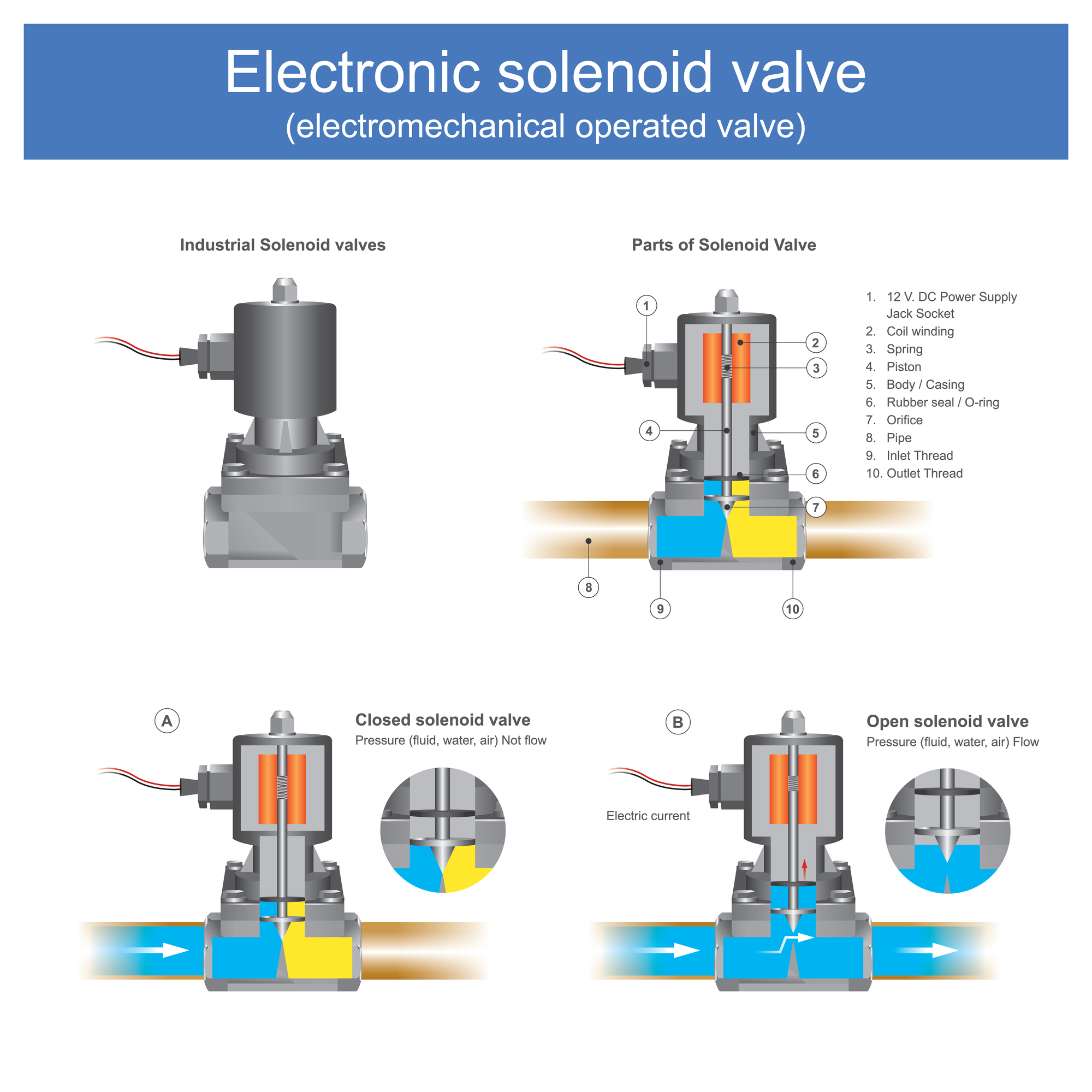

When it comes to brewing, every single detail matters, from the selection of ingredients to the control of the liquid flow. Among the many components involved, solenoid valves stand out as a key player in ensuring the quality and consistency of the final product. Often unnoticed, these valves are essential in managing the flow of liquids throughout the entire brewing process, from mashing to fermentation and beyond. Solenoid valves are vital for maintaining accuracy when it comes to liquid flow and distribution in brewing. Their ability to operate with precision and reliability makes them indispensable across various stages of the brewing process. As brewing technology continues to evolve, the demand for higher efficiency and consistency has spurred significant advancements. At the core of this transformation lies the following: Choosing the right solenoid valve is essential for meeting the specific needs of any brewing operation. In the complex world of brewing, every component, regardless of its size, plays a significant role. Solenoid valves, in particular, are instrumental in managing the flow and quality of liquids, directly impacting the efficiency, safety, and flavor consistency of the brewing process. For breweries aiming to optimize their operations, investing in the right solenoid valves is not merely a technical choice—it’s a pledge to excellence in brewing. Answer: Yes, indirectly. By enabling precise control over the flow and temperature of liquids, these valves contribute to maintaining consistency in the brewing process, which is vital for preserving the intended flavor profile of the beer. Consistent temperatures and ingredient blending result in a more reliable and superior final product. Answer: A solenoid valve is an electromechanically operated valve designed to control the flow of liquids. In brewing, it operates by opening or closing in response to an electrical signal, allowing for precise control over liquid ingredients like water and wort during different stages of the brewing process. This level of precision ensures consistency in both flavor and quality in each batch of beer. Answer: Solenoid valves promote sustainability by optimizing liquid usage and reducing waste. By accurately controlling the flow of water and other liquids, they help minimize resource consumption, which is increasingly important in environmentally conscious brewing practices. Additionally, their durability and long lifespan contribute to a reduced environmental footprint.

For Water Supply 20-160mm PPR Pipe Production Extrusion Line Machine

PPR pipe production line is capable of manufacturing PPR cold and hot water pipes of different diameters and thicknesses.

PPR pipe production line is capable of manufacturing different sorts of pipes such as PPR cold/hot water pipes and PE silicon pipes. This production line can also produce monocolour pipe with one extruder and multicolour pipe with co-extrusion die head.

Equipment List:

This pipe line includes single screw extruder, co-extrusion die; Vacuum calibrating water tank, water spraying tank, haul-off machine, cutting machine, stacker

Vacuum Calibrating Water Tank: The body uses good quality stainless steel board equipped with ABS nozzle and anti-blocking impurities structure. It has long service life and the frame can be adjusted from three dimensions. There is roller in the shade.

Haul-off Machine: It adopts frequency convertor, pneumatic clamping and working simultaneously with the whole extrusion line.

Ppr Pipe Making Machine,Ppr Extusion Line,Ppr Pipe Making,Ppr Pipe Manufacturing Machine KonRun Intelligent Machinery(Ningbo) Co., Ltd. , https://www.konrunmachine.comIntroduction

Precision in Liquid Handling

Selecting the Right Solenoid Valve

Conclusion

Frequently Asked Questions:

Can the use of solenoid valves affect the taste of the beer?

What is a solenoid valve and how does it function in brewing?

How do solenoid valves contribute to sustainability in brewing?

Single Screw Extruder: High speed and efficiency It is ceramic heating which assures good plasticization and uniform heating of raw materials. Also it assures high speed and stable production and great output.

Co-extrusion Die: Unique five layer co-extrusion technology ensures high and stable quality for aluminum plastic composite pipe. Advanced calibrating technology can develop the calibration quality.

Water Spray Cooling Tank:The body is made of stainless steel and the shade is transparent soft PVC curtain which ensures good cooling effect.