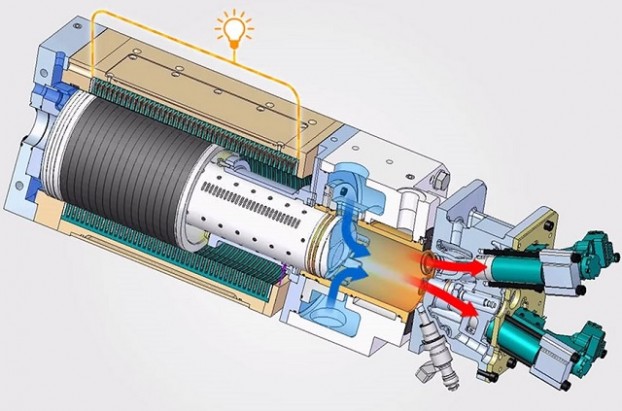

The familiar rhythm of the Otto cycle—Suck, Squeeze, Bang, Blow—has long defined the backbone of modern engines, remaining largely unchanged for almost a century. While significant advancements have occurred in fuel management systems, ring efficiency, and bearing designs over the years, the four-stroke Otto cycle remains dominant. However, despite its widespread adoption, there have always been whispers of alternatives. Toyota's Atkinson cycle hybrid engines, for instance, have shown promise when paired with hybrid batteries and powertrains. Similarly, Mazda's Wankel rotary engines have captured the hearts of enthusiasts since their introduction in the late '60s. Recently, Toyota unveiled yet another contender in the world of internal combustion engines—the Free Piston Engine Linear Generator (FPEG). This innovative design could potentially replace traditional gasoline engines in hybrid vehicles by acting as a single-purpose generator. The FPEG concept has generated excitement not only because of its potential to enhance efficiency but also due to its unique approach to power generation. Toyota FPEG Engine At first glance, the term Free Piston Engine Linear Generator might sound complex, but the underlying principle is surprisingly straightforward. Picture a long, sealed cylinder housing a double-sided magnetic piston, with two combustion chambers—one at each end of the cylinder—and a set of electrical coils surrounding it. As combustion occurs in one chamber, it pushes the piston back and forth, compressing and igniting the air-fuel mixture in the opposite chamber. This rapid reciprocating motion generates electricity directly, without the need for a crankshaft or conventional valvetrain. This simplicity offers several advantages: no crankshaft to maintain balance, fewer moving parts, fuel flexibility (capable of running on gasoline or diesel), and enhanced efficiency. Although it's too early to predict exact efficiency levels, it's reasonable to assume the FPEG could surpass current standards. While it may not deliver high torque, its ability to produce clean, reliable electricity makes it an ideal candidate for hybrid vehicles. Note: The video illustrates a single-sided version of the FPEG. Imagine two such units working together to share a common piston for improved performance. Toyota envisions the FPEG being integrated into hybrid cars as a compact, lightweight, and durable solution. Although it might take several years—or perhaps never reach production—it holds immense potential. Toyota believes this technology could eventually replace the Atkinson cycle engines currently used in the Prius series. It’s still uncertain whether the FPEG will ever grace dealership showrooms, but its promise is undeniable. On one hand, the FPEG represents a leap forward in efficiency and design. On the other, it challenges established solutions that already work effectively. If Toyota manages to overcome the hurdles of affordability and scalability, the FPEG could become a game-changer. Its small size, high efficiency, and durability make it an attractive option for urban vehicles or even as a backup power source for electric vehicles. Toyota has a history of turning skeptics into believers. When they introduced the Prius, many doubted the viability of hybrid vehicles. Yet today, hybrids are mainstream. Whether the FPEG becomes a reality or remains a concept, Toyota’s commitment to innovation is evident. One thing is certain: if anyone can make the FPEG viable, it’s Toyota. In the meantime, the automotive industry continues to evolve, with new technologies emerging every day. The FPEG represents just one piece of the puzzle, but its potential impact on the future of hybrid vehicles cannot be ignored. For now, we wait and watch as Toyota navigates the path toward bringing this groundbreaking concept to life. Ultra Thin Metal Foil and Strip

ultra thin Titanium & stainless steel strip / foil metal material, HS 8108903290 or 8108903100

We are a professional manufacturer of cold-rolled stainless steel sheets and coils with a designed production capacity of 660,000 tons. Our main products include steel grades 300 and 400 series, with surface finishes such as 2B, 2D, No.1, No.3, No.4, HL, BA (bright annealed), hard state, embossed and matte finishes. 304 201 Strip,Alloy 4J36,Ti Foil Strip,Iron-Nickel Alloy Invar 36 Ningbo Boss Metal Material Co., Ltd. , https://www.boss-metal.com

The Promise of the FPEG Concept

Will the FPEG Make It to Market?

Related Posts

2014 Toyota Tundra SR5 Is A Show Stopper

2014 Toyota Tundra SR5 Is A Show Stopper

President Toyoda’s Favorite Non-Toyota Vehicles

President Toyoda’s Favorite Non-Toyota Vehicles

Cue The Dramatic Music…

Cue The Dramatic Music…

Battery Production Change

Battery Production Change

Toyota Responds Swiftly To Brake Issues

Toyota Responds Swiftly To Brake Issues

Toyota Faces Problems With Soviet Patent-Holder

Toyota Faces Problems With Soviet Patent-Holder